Hyfax Saving Techniques

Technique #1:

Excessive slide runner wear can be caused by many situations. In many regions, poor or late snow

conditions,

over the past several years, have been a major contributing factor. However, even in the best of snow conditions, there are other important factors that affect slide runner wear.

*

Track

Lug Height:

Current snowmobiles have significantly taller lugs than previous sleds. The height of the track lug directly affects how much lubrication the slide runner receives.

Taller lugs = more distance from the snow surface, which = less lubrication getting into the sliding surfaces.

*

Unit weight: Current snowmobiles are heavier than previous

years.

Higher unit weight = higher pressure on the sliding surface, which = more heat and higher required levels of lubrication.

*

Track

weight: Today's snowmobiles

have higher top speed capabilities. Higher top speeds require the track to be more heavily constructed to withstand sustained top speed runs. The taller lugs of mountain tracks further increase track weight. The heavier tracks do not dissipate heat as well as lighter tracks. Higher forces are also transmitted on the slide runner at the heavier track's re-entry point at the front of the rail.

Higher track weight = increased force and track heat, which = higher required levels of lubrication.

*Higher average speeds: The average trail speeds have increased significantly over the years due to advances in suspension designs and improved grooming of trails. Higher speeds

mean two things:

More heat build-up in the track and greater force on the slide runner at the track's re-entry point at the front of the rail regardless of track weight.

Higher average speeds = increased force and track heat, which =

higher lubrication requirement.

*Long travel rear suspension systems: Long

travel rear suspensions create

more heat in the track due to additional flexing. Even at the same speed, a long travel suspension causes the track to run at a higher temperature than a short version. A long travel suspension = higher track heat, which = higher required levels of lubrication.

*Increased power output: The higher horse- power levels of modern snowmobiles work the track harder than ever. This means more strain

on the track.

This in turn causes more flex, which translates into higher track temperatures. Higher power output = higher track heat, which = higher required levels of lubrication.

Understand that all of these factors will greatly affect the life span of their

slide runners. This can also explain how two snowmobiles ridden in the exact same conditions may experience major differences in slide runner wear.

REMEDY:

A quick way to reduce slide runner wear, in some conditions, is to reduce the

pressure against the snow at the front of the rail. Reduce the center shock

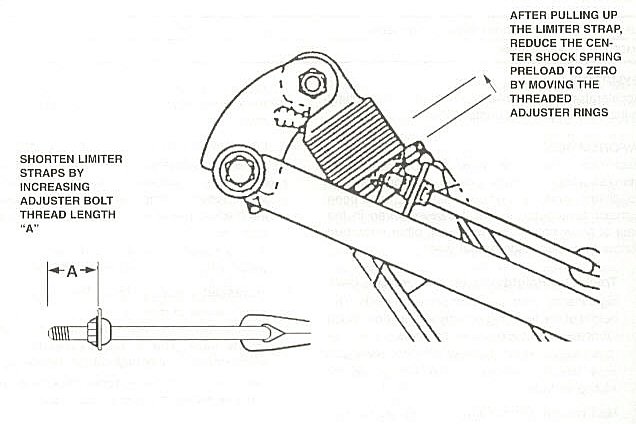

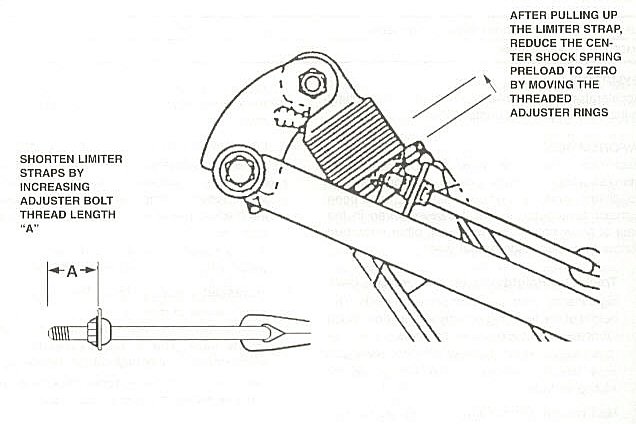

pressure by raising the rear of the unit, shortening the limiter strap and then setting the center shock spring preload to zero (see illustration below).

Example: On '00 - '01 SRX models, shorten the limiter strap by increasing the adjuster bolt thread length (A) to 42mm. After shortening the limiter strap, reduce the center shock spring preload to zero by moving the threaded adjuster rings.

Suspension settings: Stiffer center shock! spring settings to increase weight transfer or big bump capability results in more pressure against the slide runner at the front rail area.

Increased force at the front rail area = higher friction and heat, which =

lubrication requirements.

** Page 5-13 & 5-14 of 2001Technical Update Book

Technique #2:

1st thing to try would be to pull the limiter straps up about 3/4",

2nd thing would be to soften the rear suspensions to give the skid a little more sit in.

3rd would be to purchase some hyfax saver wheels from a after market source ( Bender, Maxx. Perf......etc..)

4th

The idlers from 83-00 Indy's size 5.35", will fit right on the

Yamaha. Just use the plastic spacers from the Yami and bolt them on. They will

replace the Yamaha 5.125" and give you the same oversize as the

Maxx, Perf. wheels. Aftermarket replacement shops make these a

cheap alternate.( Tip from Nitro)

5th Run sled down the road W.O.T. to get slide's hot and quickly cool off slide's to harden the surface this will help prolong hyfax life.

Technique #3:

Take a new set of hyfax and get your drill. You'll need a 3/8" bit and some strength cause you will be tired after doing two hyfax full length. Start at either end it don't matter cause you are going full length with the pattern. Drill two holes side by side followed by one and repeat. It should look like a five on a dice set ,you get it. Just dimple the hyfax to just above the depth line (about 3/8" deep) if you go to shallow or to deep don't worry. If you go through a few times, slow drill down. If you do go through it is not a big deal. That will give you the chance to look at the thickness left on the hyfax. I choose to drill through in the key wear areas anyway so at any given time I can flip my sled up and look to see how much I actually have left. Now your asking what is this going to do... well it will put snow and ice in those holes and when they get hot it will release the liquid as coolant and lubrication for the hyfax. Also if you come to an area with dirt or low snow the holes are filled with good snow, it will melt and continue to lube your hyfax and wash out the dirt and sand untill you can get to some good snow which should be soon. For you racers this also lets you run on less of a friction area due to the amount of holes (your running on air, snow, ice or liquid ie artificial lubrication wink wink) and it may give you not only extended hyfax life but, a mileage increase, less rolling resistance, and possibly free up some small amount of track hp. With this mod and tightening your limiter straps a little to change attack angle slightly on the track, and most importantly LOOSEN YOUR TRACK. Yamaha runs them at 7/8"- 1" at 22 lbs of pull and that is WAY TOO TIGHT!!! I CAN'T STRESS THAT ENOUGH. Now don't go out and loosen it too much. (your studs and lugs will start hitting and then there's another set of problems) my suggestion (and that's all it is), is to set your track in the middle of the guides (checking for straightness) and set the tension to 1-1/4" to 1-3/16" at 16 lbs of pull. if this is too loose and it ratchets or hits tighten each side equally in small increments till it goes away. Hope I've helped and here are some pics for your viewing pleasure.

By: skidooboyedk

Technique #4:

The idlers from 83-00 Indy's size 5.35", will fit right on the Yamaha. Simply remove the plastic spacers that came with the new wheels and remove the plastic spacers from the old wheels and put those old spacers on the new wheels. This allowed the stock, round metal spacer to fit within the wheel and then back on the rail brack Just use the plastic spacers from the Yami and bolt them on. They will replace the Yamaha 5.125" and give you the same oversize as the Maxx, Perf. wheels. Aftermarket replacement shops make these a cheap alternate.

The part number from JR Graham is as

follows:

KX411667

I paid $69 for four wheels and that included shipping

By: Ecopter

Any questions please post them on the Message Board or TY Forum.

Totallyamaha is not responsible for any damages that these modifications may cause to your vehicle; any modifications are your responsibility if you choose to do so. We are providing information ONLY. Some of these modifications may VOID your warranty and that is your responsibility to look into. The Totallyamaha users have passed along most of the information found on this site. If you have any questions or concerns about anything on this site talk to your dealer before using any of the information. Totallyamaha will not be liable for any damages or personal injury from any modification performed from this site.